|

|

|

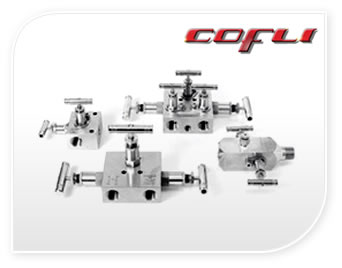

Manifold Valves

|

|

|

Applications

Pressure & Diferential Pressure Instrumentation.

Features

2 Valves, 3 Valves, 5 Valves Instrument manifolds

Stainless Steel Construction.

MSS Flange connections available.

Packing Below threads to prevent lubricant washout.

Specifications

Maximum Working Pressure:

6000psi(414bar)@100˚F(38˚F)

Working Temperature Range:

60˚F

to 450˚F(-54˚C to 232˚C) with PTFE packing

up to

1200˚F

(649˚C) with Graphite packing. |

|

|

|

|

|

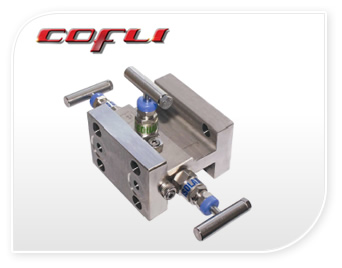

Manifold ADM-PROT

|

|

|

Description

The economical ADM-PROTM range of compact, air distribution

manifolds come in our standard configuration (shown below) or to

client specifications. ADM-PRO™ can be supplied with up to 40

take-off valves. Inlet and drain connections are threaded as

standard however, can be made to your specification, this includes

flanges i.e. 150 lbs. RF. or even socket / butt weld. Mounting legs

are supplied as standard to make installation easier. Take off sizes

can vary from 1/4” to 1” in size. Working pressures range from 750

psi version up to 10,000 psi. Other options such as hand wheels

and locking devices can be supplied.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Ingress seal fitted as standard.

Repair / service kit available to extend field life further.

Full material traceability.

100% Hydrostatic testing.

Material of construction can be supplied to meet the

requirements of NACE MR-01-75 |

|

|

|

|

|

Manifold Valves NVDM

|

|

|

Description

The Alco NVDM compact, integral needle valve type, high

integrity distribution manifolds come in our standard configuration

(shown below) or to client specifications. NVDM can be supplied

with up to 20 take-off valves. Inlet and drain connections can be

made to specification, this includes flanges i.e. 150 lbs. RF

socket / butt weld, threaded or even compression type tube

connectors. M10 base mounting holes are supplied as standard

to make installation easier. Take off connections are 1/4” or 1/2”

in size. Working pressures range from vacuum up to 6,000 psi &

10,000 psi. Valve orientations come in 3 formats type A, B or C

for ease of use and maximise space envelope utilisation and

operator access.

Features

Maximum temperature 230°C (570°C with GP option).

Base mounting holes to allow fixing to enclosure or

mounting boss.

Repair / service kit available to extend field life further.

Full material traceability.

100% Hydrostatic testing.

High Pressure (up to 10,000 psi). |

|

|

|

|

|

2VR Series

|

|

|

2 Valve Manifold 6,000 psi and 10,000 psi rated

Description

The two-valve isolating and venting manifold used mainly in gauge and

static instrument applications such as pressure switches, pressure

transmitters and manometers. The manifold will isolate instrumentation

from the process and allow venting of the instrument for calibration /

removal from the circuit without effecting the process / application and

or recovery of a sample etc. Standard 1/2” inlet x 1/2” outlet with a 1/4”

vent port supplied plugged as standard for safety. Incorporated are all

the standard long service life features of the standard ‘N’ series needle

valve, multi-ring piston style packings, back sealing facility. Safe antirotational

cam locking device. Most standard options such as locking

devices are available. Mounting holes supplied as standard for pipe or

wall mounting to suit quick installation.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Accurate and fine control of venting.

l Repair / service kit available to extend field life further.

Ingress seals fitted as standard.

Mounting holes as standard to allow for fixing to pipe

stands or enclosures.

100 % Hydrostatic testing. |

|

|

|

|

|

2VG Series

|

|

|

In-line 2 Valve Manifold 6,000 psi and 10,000 psi rated

Description

The ‘2VG’ series 2 valve gauge manifold offering single process isolation

and controlled venting. Unlike the ‘2VR’ series, the ‘2VG’ series can be

offered with male inlet and female outlet connections. Available 6,000 psi

and 10,000 psi versions, a slim-line and compact 2 valve manifold (vent

port plugged as standard).The ‘2VG’ series, utilises metal to metal seat

and body to bonnet connection for superior, bubble tight sealing

capabilities at both extreme pressures and temperatures. The "2VG"

series also offers non-rotating hardened tip for extended service life. The

unique anti-vibration cam locking safety device at the body bonnet

connection is for extra safety. Maximum working temperature up to 230°C

and up to 570°C with -GP option at reduced pressure. Many options

available including hand wheels and locking devices.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Repair / service kit available to extend field life further.

2” and 4” extended versions are available.

i.e. 2VG4NS – Ext. 2” = 2” Extended

2VG4NS – Ext. 4” = 4” Extended.

Full material traceability. |

|

|

|

|

|

2VBD Series

|

|

|

Direct Mount 2 Valve Manifold 6,000 psi and 10,000 psi

rated

Description

Two valve direct mount manifold, designed for use with

pressure transmitters. The manifold will isolate instrumentation

from the process and allow venting of the instrument for

calibration / removal from the circuit without effecting the

process / application and or recovery of a sample etc. This

compact unit offers single isolation, and vent / test facility. Vent

port 1/4” NPT (vent port plugged as standard for safety).

Supplied with bolt pack and seal as standard. The 2VBD can

be supplied with additional tapped holes in it’s base for

mounting purposes. Other options apply such as anti-tamper,

lockable vent valve.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

High temperature version up to 570°C with graphoil

option (-GP).

Valve flow can be reversed so as calibration can take

place in situ.

Ingress seals fitted as standard.

Full material traceability. |

|

|

|

|

|

2VBM Series Base Mounted

|

|

|

Description

Two valve direct mount manifold for base mounting to an

enclosure or mounting plate, designed for use with pressure

gauge transmitter. The manifold will isolate the

instrumentation from the process and allow safe venting of the

instrument for calibration / removal from the circuit without

effecting the process / application and or recovery of a sample

etc. This compact unit offers single isolation, and vent / test

facility. Vent port supplied 1/4” NPT (vent port plugged as

standard for safety). Being base mounted facilitates quick and

easy installation of the instrument. No additional fitting or

brackets required, the manifold supports the instrument.

Supplied with bolt pack and seal as standard.

Features

Bubble tight metal to metal seat for positive shut off.

l All valves have 2-piece non-rotating hardened (17-4PH)

tip for first time seal. Every time.

Temperature rating -50°C to 230°C (570°C with GP

option).

High temperature version up to 570°C with graphoil

option (-GP).

Pressure responsive multi-ring / piston packing for

compression and pressure dynamic sealing.

Metal to metal body bonnet seal for high pressure and

high temperature sealing. |

|

|

|

|

|

3VR Series

|

|

|

Description

The three-valve isolation manifold remote mounted (pipe to

pipe). Used mainly in differential pressure transmitters and

static instrument applications. The 3VR has two process

isolation valves and one equalisation valve to equalise the

two sides. Standard 1/2” inlet x 1/2” outlet. Incorporated all

the standard long service life features of the standard “N”

series needle valve, multi-ring piston style packings, back

sealing facility. Safe anti-rotational cam locking device. Most

standard options such as locking devices are available.

Mounting holes supplied as standard for wall or bracket

mounting. Process and instrument sides are both on 54mm

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Ingress seals fitted as standard.

Available in 316 Stainless Steel, Monel, Duplex & other

exotic materials.

Mounting holes as standard to allow for fixing to pipe

stands or enclosures.

100 % Hydrostatic testing |

|

|

|

|

|

3VBD Series

|

|

|

Description

Direct mounted three-valve manifold, instrument mount

to pipe connection. Offering two isolation valves, and

one equalising valve for differential pressure

transmitter or static instrument applications. Supplied

with bolt pack and spare seals as standard. This slim,

compact 3-valve manifold offers all the features of

Alco’s high integrity needle valve head design

incorporated in one common instrument manifold block

that mounts directly to an instrument.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

High temperature version up to 570°C (-GP)

Available in 316 Stainless Steel, Monel, Duplex & other

exotic materials.

Base mounting holes to allow fixing to enclosure or

mounting boss. |

|

|

|

|

|

3VD Series

|

|

|

Description

Direct mounted three-valve manifold, instrument mount to

pipe connection. Having a “T” section body format allows

reasonable space envelope between the instrument and

process lines. The 3VD offers two isolation valves, and

one equalising valve. Supplied with bolt pack and spare

seals as standard. This slim, compact 3 valve manifold

offers all the features of Alco’s high integrity needle valve

head design incorporated in one common instrument

manifold block.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

54mm (2 1/8”) instrument centres.

Unique bonnet locking cam.

Full material traceability.

100% Hydrostatic testing |

|

|

|

|

|

3VBM Series Base Mounted

|

|

|

Description

Three valve direct mount manifold for base mounting to

an enclosure or mounting plate, designed for use with

pressure transmitter. The manifold will isolate the

instrumentation from the process and allow safe

equalisation between the high pressure and low pressure

sides of the pipe-work arrangement without effecting the

process / application. Being base mounted facilitates

quick and easy installation of the instrument. No

additional fitting or brackets required, the manifold

supports the instrument. Supplied with bolt pack and

seals as standard. The 3VBM can be supplied with

additional steam trace porting. Other options are available

such as locking / anti-tamper equalisation valve.

Features

Pressure responsive multi-ring / piston packing for

compression and pressure dynamic sealing.

Metal to metal body bonnet seal for high pressure

and high temperature sealing.

Unique bonnet locking cam. No accidental removal

of head unit, or loosening due to vibration. |

|

|

|

|

|

5VR Series

|

|

|

Description

Remote mounted, pipe to pipe configuration five valve manifold.

Offering two isolation valves, two vent valves and one equalising

valve. Used in differential pressure transmitters and static instrument

applications. Standard 2 x 1/2” inlet x 2 x 1/2” outlet all on 54mm

instrument centres with 2 x 1/4” plugged vent port supplied plugged.

Incorporated all the standard long service life features of the

standard N series needle valve, multi-ring piston style packings,

back sealing facility. Safe anti-rotational cam locking device. Most

standard options such as locking devices are available. Mounting

holes supplied as standard for wall or bracket mounting. All

additional ports supplied plugged as standard.

Features

Temperature rating -15°C to 170°C (570°C with GP

option).

Available in 316 Stainless Steel, Monel, Duplex & other

exotic materials.

54mm (2 1/8”) instrument centres.

Full material traceability. |

|

|

|

|

|

5VD Series

|

|

|

Description

Direct mounted five-valve manifold, instrument mount to pipe

connection. Having a “T” section body format allows a

reasonable space envelope between the instrument and process

lines. The 5VD offers two isolation valves, two vent valves and

one equalising valve. Supplied with bolt pack and spare seals.

This elongated 5 valve manifold offers all the features of Alco’s

high integrity needle valve head design incorporated in one

common instrument manifold block. All additional porting

supplied plugged as standard. Other options such as lockable

vent valves & hand wheel are available.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Ingress seals fitted as standard.

Direct mounting to instruments.

Available in 316 Stainless Steel, Monel, Duplex & other

exotic materials.

Full material traceability. |

|

|

|

|

|

5VBM Valve Base Mounted

|

|

|

Description

Five valve direct mount manifold for base mounting to an

enclosure or mounting plate, designed for use with pressure

gauge transmitter. The manifold will isolate the instrumentation

from the process and allow safe venting of the instrument for

calibration / removal from the circuit without effecting the

process / application and or recovery of a sample etc. This

compact unit offers single isolation, and vent / test facility. Vent

port supplied 1/4” NPT (vent port plugged as standard). Being

base mounted facilitates quick and easy installation of the

instrument.

Features

Positive no slack stem action.

Unique bonnet locking cam.

Metal to metal body bonnet seal for high pressure and

high temperature use.

Temperature rating -50°C to 230°C (570°C with GP

option). |

|

|

|

|

|

3 Valve Manifold Block

|

|

|

Description

Direct mounted three-valve manifold, instrument

mount to pipe connection. Offering two isolation

valves, and one equalising valve. Supplied with bolt

pack and spare seals. This slim, compact 3 valve

manifold offers all the features of Alco’s high integrity

needle valve head design incorporated in one

common instrument manifold block. All additional

porting supplied plugged as standard. Can be

supplied to DIN 19 213 mounting specification in the

100 bar (1,500 psi) or 420 bar (6,000 psi).

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Ingress seals fitted as standard.

Repair / service kit available to extend field life further.

Full material traceability.

l 100% Hydrostatic testing. |

|

|

|

|

|

5 Valve Manifold Block

|

|

|

Description

Direct block mounted five-valve manifold, instrument mount to pipe

connection. Offering two isolation valves, two vent valves and one

equalising valve. Used mainly in differential pressure transmitters

and static instrument applications. Standard 2 x 1/2” inlet x 2 x 1/2”

outlet with 2 x 1/4” vent port supplied plugged. Incorporated all the

standard long service life features of the standard N series needle

valve, multi-ring piston style packings, back sealing facility. Safe

anti-rotational cam locking device.

Features

Temperature rating -50°C to 230°C (570°C with GP option).

High temperature version up to 570°C (-GP)

Ingress seals fitted as standard.

Repair / service kit available to extend field life further.

Full material traceability. |

|

|

|

|

|

3 Valve H Section Manifold

|

|

|

Description

Direct mounted three-valve manifold, instrument mount to

pipe connection. Having a “H” section body format allows

compact space envelope between the instrument and

process lines. The 3VDH offers two isolation valves, and one

equalising valve. Supplied with bolt pack and spare seals.

This slim, compact 3 valve manifold offers all the features of

Alco’s high integrity needle valve head design incorporated in

one common instrument manifold block for direct mounting to

a pressure instrument available flange mount connection x

1/2” NPT female or flange x flange configuration.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Full material traceability.

100% Hydrostatic testing.

54mm (2 1/8”) instrument centres, alternative instrument

centres available. |

|

|

|

|

|

5 Valve H Section Manifold

|

|

|

Description

Direct mounted five-valve manifold, instrument mount to pipe

connection. Having a “H” section body format allows compact

space envelope between the instrument and process lines.

The 5VDH offers two isolation valves, two vent valves and one

equalising valve. Supplied with bolt pack and spare seals.

This slim, compact 5 valve manifold offers all the features of

Alco’s high integrity needle valve head design incorporated in

one common instrument manifold block for direct mounting to

a pressure instrument available flange mount connection x

1/2” NPT female or flange x flange configuration.

Features

Temperature rating -50°C to 230°C (570°C with GP

option).

Available DIN style mounting:

Form B1 = 100 bar (1,450 psi)

Form B2 = 420 bar (6,000 psi)

Full material traceability.

100% Hydrostatic testing.

2 1/8” (54mm) instrument centres, alternative instrument

centres available.

Material of construction can be supplied to meet the

requirements of NACE MR-01-75. |

|

|

|

|