|

|

|

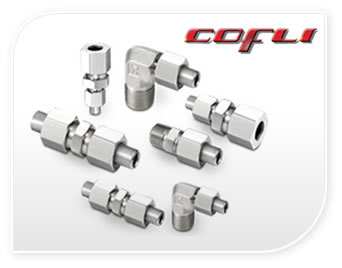

Fittings

|

|

|

Applications

Process instrumentation, High Temperaure and Cryogenic

service, High pressure service, Vacuum service.

Features

Tow errule design.

Stainless Steel, Duplex, Crbon steel, hastelloy,

Alloy400,600,825...

Gaugeaility - Vibration resistance,

Excellent Leak-Free Sealing System in high thermal

stresses and high impulse.

Specifications

Maximum Working Pressure:

9000psi(621bar)@100˚F(38˚F)

Working Temperature Range:

-320˚F to 1200˚F(-196˚C to 649˚C) |

|

|

|

|

|

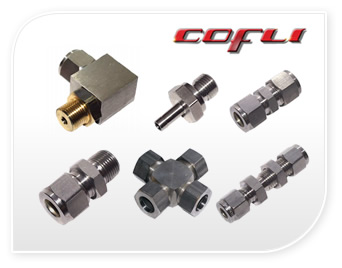

i-Fittings

|

|

|

Applications

Process instrumentation, High Temperaure and Cryogenic

service, High pressure service, Vacuum service.

Features

Tow errule design.

Stainless Steel, Duplex, Crbon steel, hastelloy,

Alloy400,600,825...

Gaugeaility - Vibration resistance,

Excellent Leak-Free Sealing System in high thermal

stresses and high impulse.

Specifications

Maximum Working Pressure:

9000psi(621bar)@100˚F(38˚F)

Working Temperature Range:

-320˚F to 1200˚F(-196˚C to 649˚C) |

|

|

|

|

|

Tube Fittings

for JIS & KS

|

|

|

Introduction

Bite

type fitting consists of three parts : BODY, SLEEVE and

NUT, and is designed to work over medium and heavy wall

tubing. See Fig.

The make up of the fitting is critical in that the tube must

be bottomed against the tube stop in the body or presetting

tool during make up. If it is not bottomed the tube will

move forward with the sleeve and a bite will not be

achieved.

Make sure the tube is bottomed. A check is possible to see

if the tube was bottomed during make up. To make this

check look at the end of the tube, and notice if a circular

appearing ring has been impressed into the tube end face.

This impression will be caused by the tube stop which has a

slight reverse angle rather than a flat face.

|

|

|

|

|

|

SAE 37º Tube Fitting

|

|

|

Applications

Hydraulic system.

Features

37˚Flare Seal.

Stainless Steel, Crbon Steel, Brass

According to SAE J514&ISO 8434-2

Useed as hose adapter.

Specifications

Maximum Working Pressure:

8700psi(600bar)@100˚F(38˚F): With O-Ring Type.

5000psi(345bar)@100˚F(38˚F): With O-Ring Type. And according to SAE J514

Working Temperature Range:

Up to 800˚F (427˚C)

Up to 800˚F (427˚C) |

|

|

|

|

|

Bite Type DIN 2353

|

|

|

Applications

Hidraulic, Compressed Air, Fuel Heating, Auto Motive.

Features

Even after repeated disassemble and remake.

Flareless Bite Type Single Cutting Ring design.

Stainless Stell, Carbon Steel, Brass Construction

According to DIN2353 & ISO8434-1

Specifications

Maximum Working Pressure:

Very Light(LL) Series PN100bar

Light(L) Series PN315bar

Heavy(S) Series PN630bar

Working Temperature Range:

-Up to 800˚F (427˚C)

|

|

|

|

|

|

Fittings & Accessories

|

|

|

Description

The following table shows the versatility of the Alco range, and the many different types of end connections and options that can be

used to build a valve to suit your requirements. Examine at your leisure the different options displayed below, perhaps you will find

just what you need – if not please do not hesitate to contact us for further details.

Categories

Single & Twin Ferrule Compression

Ring Type Tube Fittings In 316ss & Super Alloys

DIN 2353 Single Ferrule Tube Fittings in 316ss

|

|

|

|

|

|

Forged Steel Socket Welding & Threaded Fittings

|

|

|

Pressure Ratings

These fittings shall be designated as pressure class 2000,3000 and 6000 fittings for threading and pressure class 3000,

6000 and 9000 for socket-welding. This designation identifies the fittings with their ratings as shown as follows, Table 1.

Size identification

The size of a fitting is identified by the nominal pipe size. For reducing fittings, the size of the largest run opening is to be

given first, followed by the size of the opening opposite of the same run. The branch size of a Tee is given last. Where the

case is a Cross, the largest side-outlet is thirdly given, then the opening opposite |

|

|

|

|